Best Ice Cream Factory: Fresh & Fun!

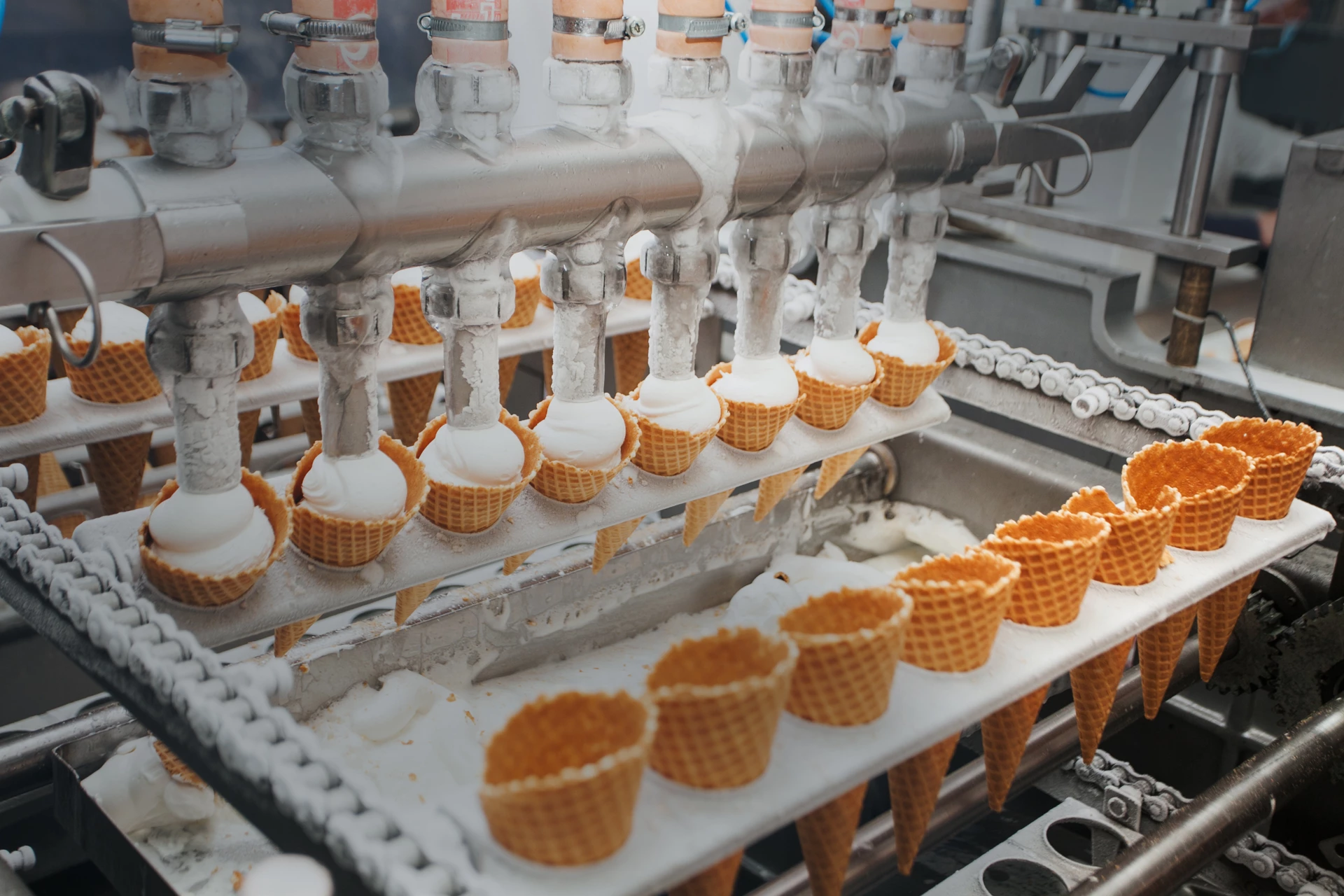

A facility where frozen desserts are produced on a large scale, typically employing automated machinery and specialized equipment. These establishments transform raw ingredients into various flavors and formats, catering to both individual consumers and commercial vendors.

The significance of these operations lies in their capacity to meet widespread demand, offering a readily available source of frozen confections. Historically, production occurred on a smaller, localized scale; however, technological advancements have enabled greater efficiency and expanded distribution networks, influencing dessert preferences and consumer habits.

Subsequent sections will delve into the processes within such a manufacturing environment, the diverse product lines created, and the logistical considerations involved in distributing these temperature-sensitive goods to markets.

Frequently Asked Questions About Ice Cream Production Facilities

The following addresses common inquiries concerning the nature and operation of large-scale frozen dessert manufacturing plants.

Question 1: What types of safety regulations govern production in these plants?

Ice cream manufacturing operations are subject to stringent health and safety standards mandated by regulatory bodies. These include protocols for hygiene, temperature control, pasteurization, and allergen management to ensure product safety and prevent contamination.

- Opus Ocean Grille

- La Quinta Inn By Wyndham Chicago Willowbrook

- Metro 112 Apartments

- The Club At Harpers Point

- Waldo Flea Market

Question 2: What is the typical lifespan of equipment utilized in this type of production?

The lifespan of equipment varies depending on factors such as usage frequency, maintenance schedules, and the specific type of machinery. Generally, with proper upkeep, major equipment such as freezers and pasteurizers can operate for several decades, while other components may require more frequent replacement.

Question 3: How does automation affect the workforce within these facilities?

Automation enhances efficiency and increases production capacity. While it may reduce the need for some manual labor, it also creates demand for skilled technicians to maintain and operate automated systems, as well as for roles in quality control and product development.

Question 4: What measures are taken to ensure product consistency across large production volumes?

Quality control measures are implemented throughout the manufacturing process, from ingredient sourcing to final packaging. These include rigorous testing of raw materials, monitoring of processing parameters, and sensory evaluations to maintain uniformity in taste, texture, and appearance.

Question 5: What is the environmental impact of these large-scale manufacturing operations?

Large-scale manufacturing processes can have significant environmental impacts, including energy consumption, water usage, and waste generation. Facilities often implement sustainability initiatives to mitigate these effects, such as energy-efficient equipment, water recycling programs, and waste reduction strategies.

Question 6: What are the main inputs required for an Ice Cream Production Facilities?

A large number of inputs include water, milk, and flavorings. Electricity also serves as one of the major inputs. Packaging inputs for cups, boxes are also important to the production process.

Understanding the operations and challenges associated with these facilities provides valuable insight into the complex process of delivering frozen desserts to consumers on a large scale.

The subsequent discussion will address different production methods commonly employed within these plants.

Tips for Optimizing Frozen Dessert Production

The following outlines practical recommendations for enhancing efficiency, quality, and sustainability within a large-scale frozen dessert manufacturing plant.

Tip 1: Implement Precise Temperature Control: Maintaining consistent and accurate temperature throughout the production and storage processes is critical. This prevents ice crystal formation, ensures desired texture, and prolongs shelf life. Utilize calibrated monitoring systems and regularly inspect refrigeration units.

Tip 2: Standardize Ingredient Sourcing: Establish reliable partnerships with reputable suppliers to ensure a consistent flow of high-quality raw materials. Rigorous quality control measures at the receiving dock are essential to verify ingredient specifications and prevent contamination.

Tip 3: Optimize Pasteurization Processes: Adhere to recommended pasteurization parameters to effectively eliminate pathogens while minimizing damage to milk proteins and flavor compounds. Regular calibration of pasteurization equipment is necessary to ensure compliance.

Tip 4: Minimize Air Incorporation During Freezing: Precisely control air incorporation during the freezing process to achieve the desired overrun and texture. Excessive air incorporation can lead to a product that is less dense and melts quickly.

Tip 5: Enhance Equipment Sanitation Protocols: Implement comprehensive cleaning and sanitation procedures to prevent microbial growth and allergen contamination. Regular inspection and maintenance of equipment are crucial for maintaining hygienic conditions.

Tip 6: Focus on Waste Reduction: Strategize the implementation of the waste reduction methodologies during the production process. This will help you to create an environmentally sustainable factory. Besides, less waste means more profit.

Tip 7: Improve Supply Chain Management: Monitor the demand and prepare enough materials for production. This ensures that production is maximized while no resources are wasted. This will also prevent late delivery of the product.

Adherence to these guidelines can lead to improved product quality, increased operational efficiency, and enhanced consumer satisfaction. Implementing these best practices will ensure long term profitability for the enterprise.

The subsequent section will address potential challenges faced by these production facilities and strategies for mitigating them.

Conclusion

The preceding exploration of the ice cream factory has highlighted its role in mass production, quality control, and logistical complexities. From ingredient sourcing to final packaging, each stage is governed by rigorous standards and technological innovations. The facility's impact extends beyond mere confectionary production, influencing consumer preferences and driving advancements in food processing.

As consumer demand continues to evolve and environmental concerns intensify, the onus remains on these establishments to adapt, innovate, and optimize operations. Continuous improvement in efficiency, sustainability, and product safety is paramount to ensuring the continued viability and societal contribution of the ice cream factory in the years to come. It is imperative for stakeholders to prioritize research, development, and responsible practices within this critical segment of the food industry.

- How To Patch A Hole In Drywall

- Chris Martin Kratt

- Crystal Creek Animal Hospital

- Ainsley Earhardt Swimsuit

- Acura Of Chattanooga

Network connectivity support for an ice cream factory

How Ice Cream is Made in Factories How It's Made YouTube

Ice Cream Factory